I have now heaped praise and rosy commentary on two sharpeners, my APSCO single hole sharpener and my Boston Ranger 55. The APSCO was tested with four different pencils and they turned out somewhere between terrible and bad. Three General’s Semi-Hex pencils were fed into the Ranger 55 and the results were finally something you could write home about. Now I would like to use the same make/model of pencils in both sharpeners and compare the results. I’ll also do a comparison of the cutters and the operation of the two sharpeners.

For the sharpening test I will go back to the General’s Semi-Hex pencils. These pencils are made of California Incense Cedar in the US. They are a step above the typical cheap Chinese pencil available in bulk at the local office supply store but they are not so upscale that they are a luxury product. I would consider them “good pencils” for someone who is looking for “quality”. These pencils are for people who don’t buy the cheapest option because you may get what you pay for but also won’t go premium because they may think they overpaid for what they want.

I set the tip adjustment on the Ranger 55 to M(edium), sharpened a General’s Semi-Hex, and then sharpened another General’s Semi-Hex on the APSCO. Here are the results.

Both pencils came out generally centered and the tips are as pointed as should be expected. The wood on the bottom General from the APSCO looks a bit more textured like an orange peel compared to the pencil on top from the Ranger 55 which looks considerably smoother. I would say that the bottom General is similar in appearance to what we saw previously with the Mexican made Dixon Ticonderoga.

There is some tearing of the wood near the end of its tapering where the pencil transitions to the lead – more so on the APSCO sharpened pencil than the Ranger 55 sharpened pencil. It’s also interesting to examine the lead tip itself very closely.

The tips look somewhat rough and chiseled. Can you almost imagine the cutters spinning around and scraping away the lead? The cutters hit the lead according to the spacing of the individual blade and it flattens the lead. Where there is a gap between the individual blades nothing happens. Hence we get that chiseled look. If there were more cutting blades on the helical assembly then our chiseled look would be less pronounced. Do the blades have somewhat irregular surfaces and heights along their length? In some points along the blade the cutters must dig in more and in others they might dig in less. Maybe some of the blade is even chipped away?

The tips look somewhat rough and chiseled. Can you almost imagine the cutters spinning around and scraping away the lead? The cutters hit the lead according to the spacing of the individual blade and it flattens the lead. Where there is a gap between the individual blades nothing happens. Hence we get that chiseled look. If there were more cutting blades on the helical assembly then our chiseled look would be less pronounced. Do the blades have somewhat irregular surfaces and heights along their length? In some points along the blade the cutters must dig in more and in others they might dig in less. Maybe some of the blade is even chipped away?

Let’s start examining the cutters on both sharpeners.

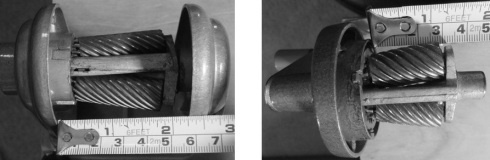

The Boston Ranger 55 cutters are on the left and the APSCO cutters on the right. Please note the scale on the measuring tape. Inches are on top and centimeters are on the bottom.

You’ll have to excuse my photography. It was difficult to capture the cutters without making shadows. Both sharpeners are screwed onto my desk so I need to perform some serious yoga to get in position for the pictures.

Let me begin by counting the blades. There are 16 cutting spiral blades on the Ranger compared to the 12 on the APSCO. The gear ratios between the inner frame gear and the gears on the cutters are the same on both sharpeners. There are 24 teeth on the frame gear and 11 teeth on the cutter’s gears. One revolution of the crank will make the cutters turn:

Gear ratio = 24 teeth ÷ 11 teeth ≈ 2.182 times.

I sharpen my pencils by turning the crank on average at approximately 2.333 rotations per second (RPS). Yes, I did time myself and it’s not hard. Just turn the crank for 15 seconds and count the number of times you turned. Divide the number of turns you counted by 15 and that’s your rotating speed. With a gear ratio of 2.182 times, the cutters turn at:

Cutter revolutions per crank turn = 2.182 times × 2.333 RPS ≈ 5.091 RPS.

Assuming it takes around 15 seconds to sharpen a squared off pencil to a point, the Ranger will have performed:

Ranger cutting operations = 5.091 cutter RPS × 15 seconds × 16 spirals = 1221.84 cutting operations.

The APSCO, with everything the same except for the number of spiral cutting blades performs a lot less cutting operations.

APSCO cutting operations = 5.091 cutter RPS × 15 seconds × 12 spirals = 916.38 cutting operations.

What a difference! The APSCO misses out on 305.46 cuts over 15 seconds. To make up for this you would think that the APSCO would take longer to sharpen the same pencil but it doesn’t seem to. I’m sure there are differences in each instance of how I hold the pencil, how much force I use, etc but there is no noticeable difference in sharpening time between the two sharpeners. Having fewer cuts in a sharpening cycle is like using rougher sandpaper in a woodworking project. That could explain the texture of the wood on the APSCO sharpened pencil being rougher.

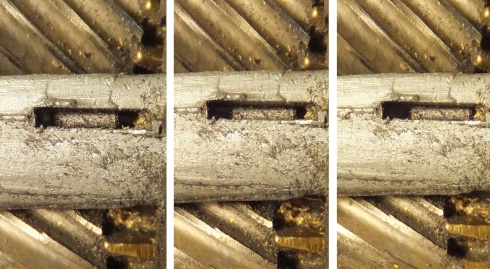

Now let’s zoom in on the blades and look at the blade surfaces. Maybe we can explain the rough tip textures. Let’s start with the Ranger 55.

You don’t even need to zoom in far to see the chips in the cutter blade surfaces. Just for the heck of it, let’s really zoom in! 🙂

You don’t even need to zoom in far to see the chips in the cutter blade surfaces. Just for the heck of it, let’s really zoom in! 🙂

It looks like someone punched out some bits of the steel along the cutter length. Strong stiff steel can be brittle. Are we seeing that here? Perhaps. The steel could have been softened but then it’s life expectancy would be lower. How does the APSCO look?

It looks like someone punched out some bits of the steel along the cutter length. Strong stiff steel can be brittle. Are we seeing that here? Perhaps. The steel could have been softened but then it’s life expectancy would be lower. How does the APSCO look?

You don’t need to zoom in to see that there are no chips along the blade but the blades are about as straight as a road paved by a drunk in some places. Let’s zoom in more.

You don’t need to zoom in to see that there are no chips along the blade but the blades are about as straight as a road paved by a drunk in some places. Let’s zoom in more.

In some places, especially in the left hand side of the picture the blade is wider and in others it is narrower. Look closely and you’ll see in some places it tends to meander. This is in contrast to the Ranger 55 cutters which may have been chipped but they were uniform and straight. I think it’s these kind of imperfections that tend to rip wood and roughen up tips.

In some places, especially in the left hand side of the picture the blade is wider and in others it is narrower. Look closely and you’ll see in some places it tends to meander. This is in contrast to the Ranger 55 cutters which may have been chipped but they were uniform and straight. I think it’s these kind of imperfections that tend to rip wood and roughen up tips.

The assembly of the sharpeners is different too. Going back to the side by side picture of the cutters of the two sharpeners you can see that the cutters in the Ranger are supported at two points in the frame. The APSCO is supported at only one side. You can remove the handle of the Ranger and the cutters stay in place but the handle on the APSCO is what holds everything together. The APSCO is definitely a lot less sturdy in that regard. It is also interesting to note the gear design in the frames.

The gear in the Ranger 55 is an integral part of the frame. It’s cast as right into it. The APSCO gear is a separate ring that is crimped into the frame. Both designs have their pros and cons. It just depends on what you want. The Ranger 55’s integral cast gear makes for a sturdy design. But, should the gear wear out then it is harder to replace half of the frame than a simple crimped in ring. To help with the wear issue, the Ranger 55 uses softer brass for the cutter’s gears. Those gears would wear out against the hard steel frame gear. The user would then have to replace the cutters as a whole which may be easier than replacing half of the frame. The APSCO could allow for a more universally adaptable design. Different sharpeners could use different cutters which may require a different gear ratio. The frame is universal so just make a new ring and crimp it in place. Done! Replacing the cutters is easier too. Just unscrew the handle and the cutters pop right out. But, the ring fits loosely and it does have some slop in it. It is necessary because the collection can is rather rigidly attached to the frame in comparison to the cutters and the frame gear. The system needs to be able to realign itself with the hole in the collection can since that hole can’t shift. The result is only one point of support for the cutters and the cutters wobble around with the ring.

Obviously, both sharpeners work but both produce a different quality of cut. Neither one is perfect but perhaps we are looking at this too closely. If you looked at your hands under a microscope even after you washed them you would see that the surface is teaming with bacteria. Under your fingernails would be a colony of vermin and disease! Yet, at some point we say our hands are clean enough and we move on. I think that’s what we have here. In my opinion, with all of its imperfections the Ranger 55 produced a superior cut. As a fan of pencils and sharpeners, I prefer the design, construction, and quality of the Ranger 55. It’s a premium product for a premium lifestyle for sure. If all you want is a sharpened pencil, like for kids to use in projects at school or home, then the APSCO may be your workhorse of choice. It can be abused, overused, and neglected yet it will still work. Think of it like a farmers old truck that smokes and sputters. It may do all that but it will work forever! The sharpener is cheap and readily available on eBay. Perhaps it’s good to have both and use them differently. Coloring pencils and cheap Chinese hardwood pencils go to the APSCO. The Generals, Palmominos, and Tombows go to the Ranger 55.

What do you think?